In-line pump dab KLME-KLPE-DKLME-DKLPE

In-line pump dab KLME-KLPE-DKLME-DKLPECirculation pumps with in-line connections are designed for use in civil and industrial heating, air conditioning, cooling and domestic hot water recirculation systems. The MCE/C inverter provides the circulation pump with maximum operational flexibility, automatically adapting the pump to different system requirements and maintaining a constant pressure drop.

TECHNICAL CHARACTERISTICS

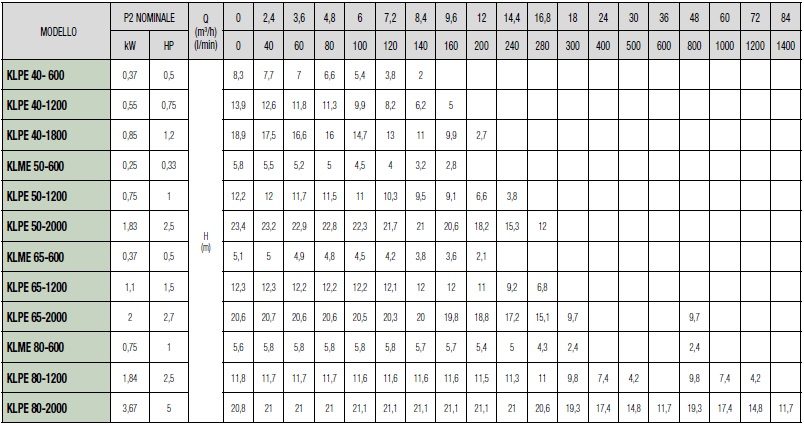

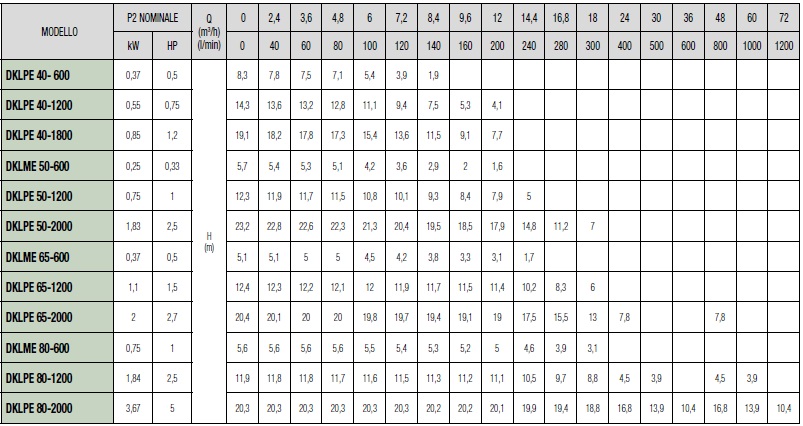

- Operating range: flow from 2 to 67 m3/h, with pressure up to 13.7 m.

- Liquid temperature range: from-15 to +120 °C.

- Pumped liquid: clean , does not contain solid and abrasive inclusions, non-viscous, non-aggressive, non-crystallized, chemically neutral, with characteristics close to water, with a glycol content of no more than 30% (regarding different percentages of glycol in the pumped liquid, please contact a technical support specialist).

- Installation: in horizontal or vertical position, the electric motor is always higher than the hydraulics.

- Max. ambient temperature: +40 °C.

- Max. operating pressure: 10 bar (1000 kPa).

- Degree of protection: IP 55.

- Insulation class : F.

- • Standard flanges: DN 40, DN 50, DN 65, DN 80 in PN 6/PN 10 (4 holes).

DESIGN FEATURES

The pump housing and motor support are made of cast iron. The suction and discharge connections are equipped with PN 10 flanges and threaded holes for pressure gauges or control sensors. To ensure installation of the pump in existing systems, the pump flanges are compatible with PN 6 counter flanges. The impeller is made of technopolymer. Mechanical seal – graphite/ceramic. The pumps are available in single (KLME and KLPE) and double (DKLME and DKLPE) versions. A check valve is built into the pressure pipe of the dual pump unit to prevent the flow of liquid when one pump is running. Also supplied with the twin pump unit is a set of blank flanges if servicing of one of the two pumps is required. The dual pump unit allows the operation of one pump, if the second is needed as a backup, or both pumps simultaneously.

The pumps are equipped with an air-cooled asynchronous electric motor: four-pole for KLME and DKLME, two-pole for KLPE and DKLPE. To ensure low noise levels and long service life, the rotor rotates on oversized bearings filled with grease for life. The MCE/C inverter protects the pump motor from overload. The design of the electric motor complies with the requirements of CEI 2-3 standards.